Imaging with narrow band H-alpha filters for solar imaging (prominences and chromosphere) requires the light beam to be almost parallel before entering the special interference filter called Etalon filter. This is achieved by i.e. telecentric systems, also extending the focal length by a factor of 2-4x. The sensor protection glass and anti-reflection glass of the camera create reflections with each other and the filter surface. Due to the parallel light beam, these reflections create interference patterns, noticable as so called Newton’s rings in the image. It depends on several different factors like sensor construction (micro lenses, …), exact angle of sensor in optical path, angle between sensor and filter / protection glass, … how strong the Newton’s rings influence the resulting images.

It is possible to reduce or eliminate this in post processing. But any minor shift in the imaging train will make it almost impossible to compensate with flat-field images.

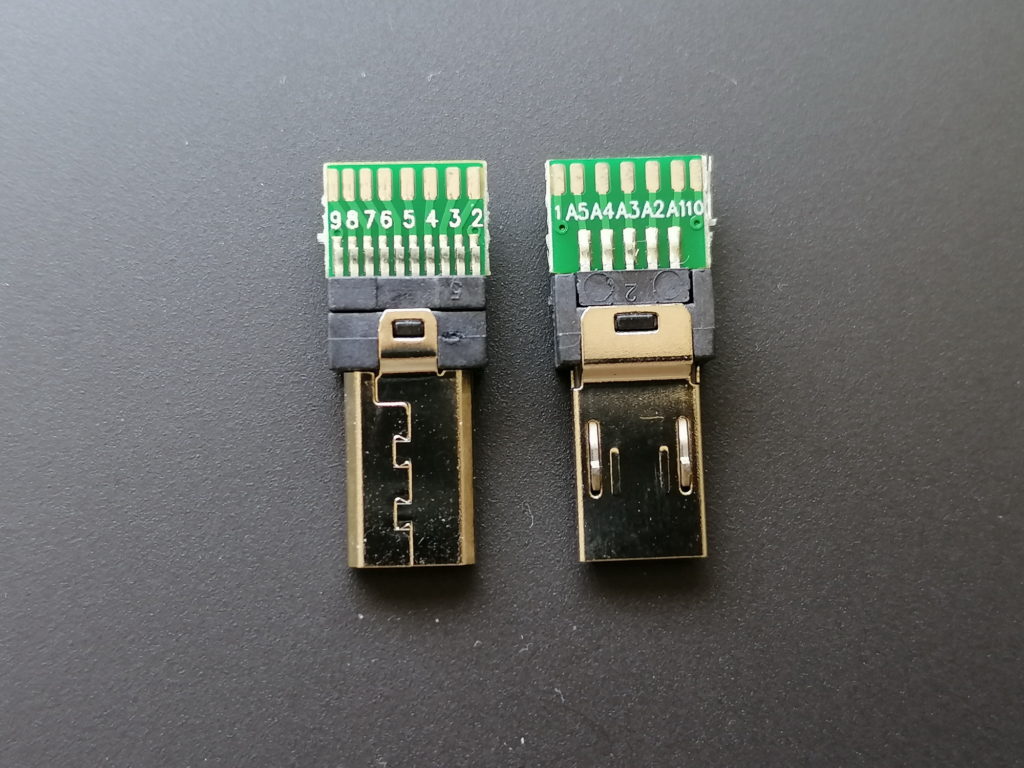

Fortunately, there is one alternative option: tilting the camera by a few degrees (usually up to 5 degrees), to widen the distance of the Newton’s rings, where they are no longer disturbing.

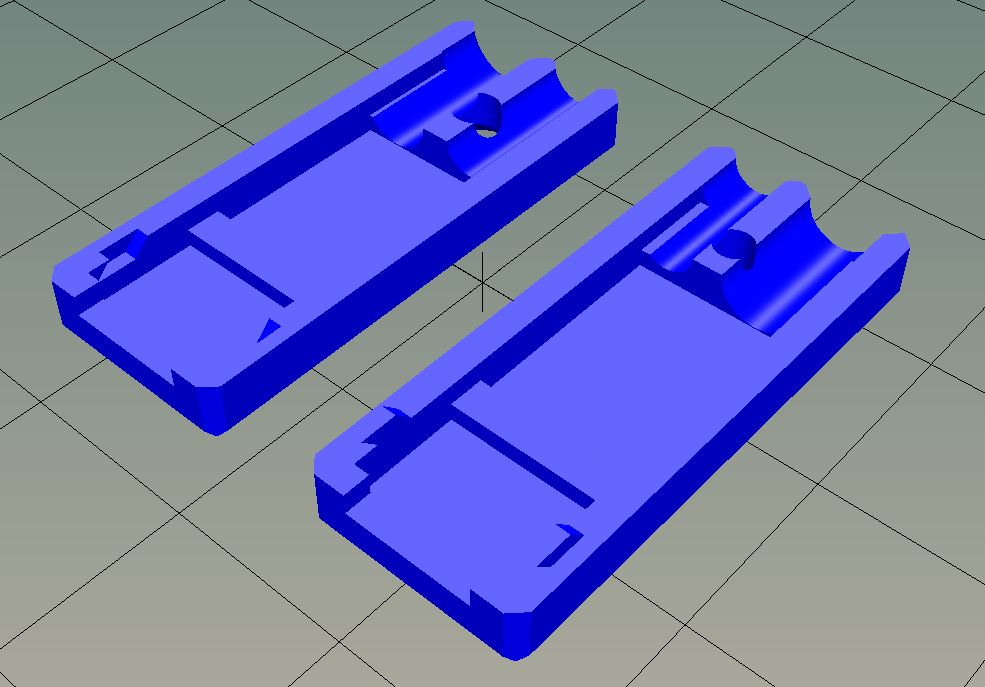

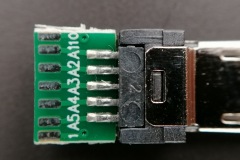

As these tilt adapters have a quite steep price tag, I constructed and printed one myself. I had to create several versions, until I had achieved a proper stability as well as stray light protection. But finally, I have a working tool 🙂

If you are interested in the design, you find the 3D files and description here: https://www.thingiverse.com/thing:4301757

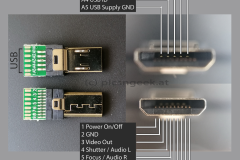

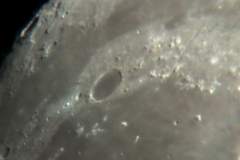

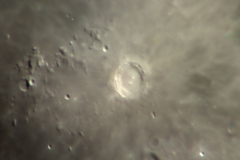

See how much the tilt changes the resulting image!

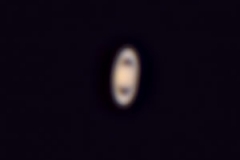

Hints to the images:

– The blurry look in the image with Newton’s rings results from the alignment algorithm locking on the Newton’s rings instead of surface features

– the adapter attached to the filter is a prototype without stray light protection. Hence a strip of black insulation tape was used for shade