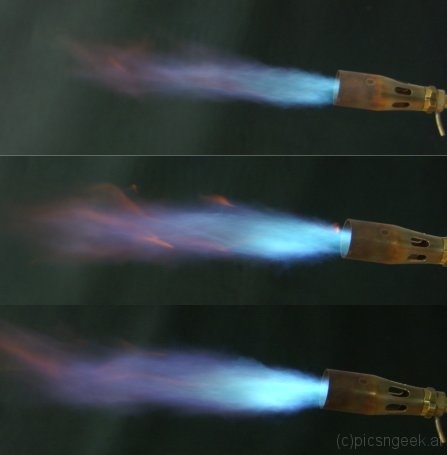

I was challenged by the need of more thermal power of one of my propane torches to melt higher quantities of metal. Furthermore, I needed to modify the characteristics of the flame, to have a neutral flame to perfectly balance the available oxigen levels as well as carbon levels around molten metal.

The first change was quite straight forward: To increase the possible thermal output of the torch, higher volume of gas has to pass through the nozzle. My nozzle had a 0.5mm hole for the gas to exit. So enlarging the size by drilling a 0.55mm hole was – apart from the rather delicate work – not so much of an issue.

The second change required to modify the air flow. My nozzles generated a somewhat carburizing flame. Therefore the available oxigen was a bit too low. When higher amounts of air may be sucked in by the gas travelling through the nozzle, the flame gets more reduzing. So I opened the air holes by small amounts from each test to the next, until my desired flame characteristics was met…